Introduction

In today’s world, packaging plays a vital role in maintaining the quality and shelf life of products. One of the most widely used and consumed materials in the packaging industry is polyethylene film. This polymer material has gained a special place in various industries due to its characteristics such as transparency, flexibility, mechanical strength and reasonable production cost. From shopping bags and agricultural films to food and pharmaceutical packaging, polyethylene film has become an integral part of our daily lives.

In this article, we will examine the definition of polyethylene film, how it is produced, suitable grades, applications, and the domestic and export market situation.

What is polyethylene film?

Polyethylene film is a thin, flexible sheet produced from the polymer polyethylene (PE). These films are usually very thin (from a few microns to a few hundred microns) and, depending on the grade used, can be transparent or opaque, hard or soft, moisture-proof or UV-resistant.

Polyethylene is a thermoplastic and is used in two main forms for film production:

- Low density polyethylene (LDPE, LLDPE) has high flexibility, transparency and softness

- High density polyethylene (HDPE) has high strength, excellent mechanical resistance

How to produce polyethylene film

Polyethylene film is produced in two main ways:

- Blown Film Extrusion

In this method, polyethylene granules are melted and then extruded through a ring die (die) in the form of a tube. Compressed air is blown into the tube and the film expands into a thin bubble. Finally, after cooling, it is collected into a roll.

Advantages: High mechanical strength, various thicknesses, wide application in packaging.

Disadvantages: More difficult to control the thickness accurately than the casting method.

- Casting method (Cast Film Extrusion)

In this method, molten polyethylene is extruded through a flat die and poured onto a cooling roller. The produced film is usually clearer and more uniform than blown film.

Advantages: Excellent transparency, precise thickness control.

Disadvantages: Higher production cost, lower strength than blown film.

Suitable grades of Polyethylene Film

Choosing the right polyethylene grade plays a key role in the quality of the produced film. Some of the most important grades used in Iran and global markets are:

HDPE Film (High Density Polyethylene Film Grade)

- Common Grades: HDPE EX5, HFI 5110, HDPE F7000

- Features: High tensile strength, good impermeability to water vapor

- Application: Shopping bags, garbage bags, industrial packaging

LDPE Film (Light Density Polyethylene Film Grade)

- Common Grades: LDPE 2420D, LDPE 2100TN00, LDPE 2420H, LFI 2130, LH0075, LFI 2185A, LFI219, 2420E02, LFI 2125A, LF 0200, 2102TX00, LF0190 and etc.

- Features: Transparency, softness, heat-sealability Excellent

- Application: Food packaging, agricultural films, packaging wrap

LLDPE Film (Linear Low Density Polyethylene Film Grade)

- Common grades: LLDPE 209AA/KJ, LLDPE 0220AA/KJ, LLDPE 235F6, LL22B01AA, LL22B02AA, LL22B03AA, LL18B03 and etc

- Features: High flexibility, puncture resistant

- Application: Stretch film, heavy material packaging, agricultural coatings

Applications of Polyethylene Film in Various Industries

1. Packaging industry

- Shopping and store bags

- Food packaging (bread, vegetables, meat and chicken)

- Pharmaceutical and health product packaging

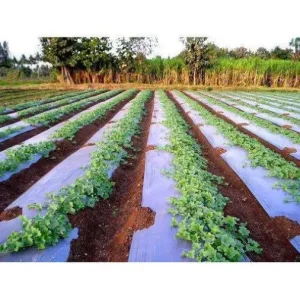

2. Agriculture

- Transparent or opaque greenhouse films

- Agricultural mulches for moisture retention and weed control

3.Construction Industry

- Dampproofing Films

- Temporary Coatings in Construction Projects

4. Automotive and Home Appliances Industry

- Stretch Films for Transport and Packaging of Parts

- Protective Coatings for Various Surfaces

5. General Consumer Products

- Garbage bags, freezer bags, protective wrap

Domestic Market for Polyethylene Film in Iran

As one of the largest producers of polyethylene in the region, Iran has a high demand market for polyethylene film.

- Advantages: Easy access to petrochemical feedstock, numerous producers at the national level, competitive prices compared to imports.

- Challenges: Fluctuations in raw material prices on the commodity exchange, export and import restrictions, high competition in the domestic market.

According to statistics, more than 60 percent of Iran’s domestic polyethylene consumption is spent on the production of various types of films (from thin packaging films to agricultural films).

Export Market for Polyethylene Film

The global market for polyethylene film is very extensive and growing. Countries in the Middle East, Central Asia, and even Africa are the major importers of these products.

Iran’s export target countries:

- Turkey: High consumption in packaging and agriculture

- Iraq: Extensive imports of polyethylene film due to insufficient domestic production

- Afghanistan and Pakistan: High-demand consumer market for thin films and packaging

- Persian Gulf countries (Oman, UAE, Qatar): High need for agricultural and industrial films

Iran’s advantage in exports:

- Geographical access to regional markets

- Competitive price compared to European producers

- Variety of production grades in domestic petrochemicals

Conclusion

Polyethylene film is one of the most important and widely used polymer products in the world today. This flexible material with various grades has a wide range of applications from packaging and agriculture to the automotive and construction industries. With its strong petrochemical infrastructure, Iran has been able to capture a significant share of the domestic and export markets. The future of this industry is bright and promising, given the global trend of increasing demand for lightweight, safe and hygienic packaging.

Get in Touch with KPPlastics

Our trading company, with extensive experience in the field of supplying and exporting polyethylene film grades (LDPE, LLDPE, HDPE), is ready to cooperate with domestic and foreign manufacturers and traders. If you are planning to buy, sell or export polyethylene film, contact our experts today to receive the best advice and services.