What is Extrusion Process of Polymer Material?

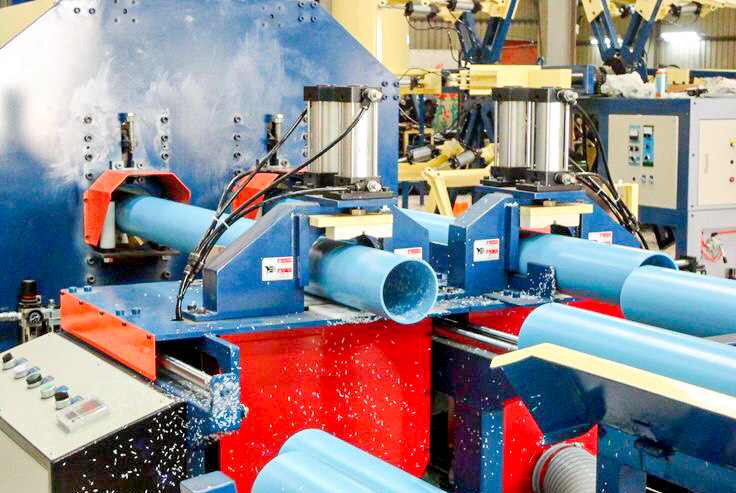

Extrusion is a method in which solid polymeric materials are first entered into the extruder through a hopper and then softened and gradually melted by the heaters inside the machine. After taking the melted material, it moves forward and finally it is taken out of the desired mold, which is called a die, to take shape, and then it hardens and turns into the desired shape by passing through the cold water tank.

Types of Extrusion

Blown Film extrusion:

It is the widely used method for the production of plastic sheets and films.

Pipe Extrusion:

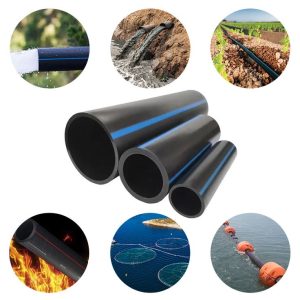

This method is used specifically for the production of kinds of pipes such as water and gas pipes, industrial pipes, power cables cover and etc.

Profile Extrusion:

It is used specifically for the production of plastic profiles for instance, door and window frames, car floor mats and etc.

Application

Production of food packaging products, stretch films, sheets, pipes and fittings, hoses, window frames and building doors, electric cable covers, covering greenhouses films, car parts, all kinds of compounds and these are several examples which they are made by extrusion method.

Industries

Construction, automotive, agricultural, plastics recycling industries.

Extrusion Grades

PP, Polyethylene:

HP510L

ZR230C

EP440G

HDPE, High Density Polyethylene:

Ex3, Ex6, Ex2, 3510, 3520, 6300, 6366M, 7700M, CRP100 Black, CRP100 Natural, PE 100 Black, PE 100 Natural, 5000S, HEX4460 PE80

LDPE, Low Density Polyethylene:

LFI 2119

LFI 2130

LFI 2125A

LEC 1969

PVC, Poly Vinyl Chloride:

S70, S65, S60,

LLDPE:

209AA

HIPS, High Impact Polystyrene:

7240

The solid plastics raw material (in form of granular, powder & flake) be melted and then molded for the production of all kinds of plastic products which are produced through extrusion process.

Afshin Karami Trading Group export plastics raw materials in grades with the ability to be extruded. Do not hesitate to contact us to be notified about the updated prices and consulted about exporting affairs.