Pakistan is one of the countries that has good potential for HDPE F7000 exporting and trading in polymer materials due to the lack of production facilities and lack of technical knowledge in this field. Since Iran allocate a small percentage of the export of polymer materials to Pakistan, Iranian businessmen can export more in this field.

Polyethylenes are very widely used polymer materials that are used in various industries all over the world today. Therefore, the exporting of HDPE F7000 to Pakistan, which is one of the widely used grades among polyethylenes, can bring a large amount of profit and foreign currency income to Iranian businessmen and traders.

In this article from Irplastics.com, we will introduce you as much as possible to the export method and characteristics of HDPE F7000 and we will mention some points about it. However, introduction to the characteristics of polymer materials is the first and most important step for trading and exporting these products.

What is Polyethylene?

Polyethylenes are polymer materials that are produced from petroleum derivatives. Polyethylenes include several groups according to their structure and molecular weight and other features. Nowadays, polyethylenes are considered to be the most popular thermoplastic materials, and most of the products are produced from combinations of these materials.

This polymer is actually a kind of light and versatile resin and is considered as a family of polyolefin resins. PE, which stands for Polyethylene, is produced through the polymerization process of ethylene. This manufactured product is a type of thermoplastic polymer that is thermosoftening and has a variable crystal structure. The meaning of soft heat is that it melts easily through heating and becomes solid again after cooling.

This polymeric material has a variable crystal structure and is one of the most widely used materials in different industries, including food packaging industries, trash bags, kinds of buckets, automobile fuel, and agricultural industry and etc. Polyethylene material has elasticity like rubber.

What are the Different Kinds of Polyethylene?

The classification of polyethylenes is based on important indicators such as monomer structure, branched and density, as well as application and etc. But generally, the most common classification for polyethylenes is based on their molecular weight and density, which include the following:

- Light or branched polyethylenes which are divided into two categories: LDPE and LLDPE with low density.

- Heavy polyethylene or HDPE that has high density. These polyethylenes are known as linear that includes high-density polyethylene (HDPE) and ultra-high molecular weight polyethylene (UHMWPE).

- Cross-linked polyethylene

In addition to this, there are sub-categories of polyethylenes available in the market, which include:

- High molecular weight polyethylene or HMWPE

- Very low molecular weight polyethylene or ULMWPE

- Relatively medium density polyethylene or MDPE

- Very low density polyethylene or VLDPE

- Chlorinated polyethylene or CPE

This division will help you to recognize polyethylene materials better and understand their features and properties. Therefore, by knowing polyethylene materials, you can promote your business and also save money.

What Does Polyethylene Means?

As mentioned, polyethylenes are formed of single units of ethylene, which are divided into different types according to their arrangement and molecular structure. This polymer material stands for “High Density PolyEthylene” and means the same.

The heavy polyethylene is a thermoplastic with a linear structure and unbranched or with little branching, which has high density and is produced at a temperature between 70-300 degrees Celsius. Also, the pressure required for this type of polyethylene is between 10-80 Bar, which causes the production of this polymer material.

In general, two sources are used for the production of heavy polyethylene, one is reforming natural gas (a mixture of methane, ethane and propane) and the other is the catalytic breakdown of crude oil into gasoline.

The appearance of heavy polyethylene is usually waxy and transparent and becomes very hard at cold and low temperatures. This product also has good flexibility and weather resistance. Heavy polyethylenes are the most widely used types of polyethylenes, which are used the most in food packaging, production of milk and fruit juice bottles, packaging containers such as trays, boxes, jam cans, garbage containers, ice boxes. They are also used to produce products such as fishing nets, agricultural industry, sports equipment, decorative and industrial products, and making all kinds of pipes and fittings and protecting telecommunication cables.

The main properties and characteristics of heavy polyethylene are as follows:

- Density between 0.97-93 g/cm3

- Excellent resistance to most solvents such as alcohol, dilute acids and alkalis

- Moderate resistance to oil and grease

- Low resistance to hydrocarbons (aromatic, halogen and aliphatic)

- It has a melting point between 120-140 degrees Celsius

- Good electrical insulation

- No water absorption

- Continuous temperature around -50 to +60 degrees Celsius

But the advantages of using heavy polyethylene materials in the final products include the following:

- High tensile strength compared to different forms of polyethylene

- They are FDA compliant

- Being resistant to low temperature

- Reasonably priced with good processing capabilities

However, this polyethylene, like other polymer materials, also has disadvantages, the main is less stiffness than polypropylenes, weak and low resistance to ultraviolet rays, and susceptibility to cracking against pressure indicated.

But among the most widely used heavy polyethylenes that are used the most today are the following grade:

- The 0035 grade, which is used to make parts with the blown molding process and has high resistance to impact, low heat degree, stiffness and good resistance to abrasion.

- The f7000 grade, which is a type of high density polyethylene material and is used in the production of thin films.

- The PE100 grade is used in the production of high pressure pipes such as water, gas and sewage because of its high resistance.

Heavy Polyethylene F7000

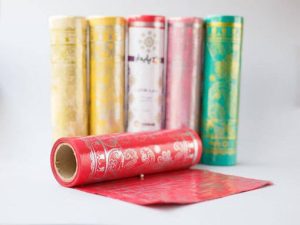

Heavy polyethylene film F7000 or HDPE F7000 grade has a high density and is used as a film. This product is a soft thermoplastic that is produced from the polymerization of ethylene gas. Also, its production process is by blowing film molding method.

One of the characteristics of this grade is its strength and high resistance to impact and chemicals. The production of this grade is at high temperature due to its durability and strength. Heavy polyethylene film F7000 is presented in both, opaque and transparent types.

This grade has a high melting point and therefore maintains its hardness at high temperatures. The main use of this grade is in the production of Nylex. If we want to have a blown film with low thickness and also dry and impactable, the f7000 grade can be used.

Maintenance and Safety of F7000 Grade

To maintain this grade, it is necessary to avoid contact with strong oxidizing substances. It should also be stored in a cool, dark and well-ventilated place. Sunlight and oxidizing agents destroy the properties of this grade.

The grade f7000 is harmless polyethylene material. So that if a person is exposed to the dust caused by this substance, it does not pose a risk to his health.

F7000 Grade Application

It is the main application of F7000 grade in the production of Nylex. The nylexes have less mechanical properties than nylons. Some nylons have lower toughness, higher brittleness and less transparency than nylons. The major use of nylons is in making food shipping bags, trash bags, disposable tablecloths and gloves, freezer bags and etc.

Also, other important application of F7000 grade include the following:

- Production of fishing ropes and nets and etc.

- Plastic household appliances such as food storage containers and plastic kitchen appliances and etc.

- Production of pipes and fittings, protection of electric cables and etc.

Price and Purchase of Heavy Polyethylene F7000 :

Because this grade has high demand in the market, its price is low and its resistance and strength are high. The main producers of this grade are Ilam, Mehr and Miandoab petrochemicals. However, the purchase and sales of F7000 grade of Mehr petrochemical production has more fans.

However, many factors affect the price of f7000 heavy polyethylene that the one of these important factors is manufacturer’s company. Also, due to the economic crises and things like the price of the dollar, the price of petroleum, the amount of supply and demand, the amount of competition among the producers and buyers in the stock market, the prices of other regions and etc. The price of F7000 grade is changeable and the diagnosis of the price and original quality from the fake type sometimes causes problems for buyers.

Afshin Karmi trading team is one of the main suppliers of f7000 grade, which is active in the field of supplying and providing the polymer materials with appropriate quality and reasonable price. This company has been able to provide optimal services to traders and economic activists in this field, meet their needs and supply the best polymer products and plastic raw materials to its customers.

All polymer materials supplied by Irplastics are delivered to buyers with a guarantee and reasonable price. You can contact us via Afshin Kerami’s commercial team to inquire about the updated price and purchase the f7000 grade. F7000 polyethylene is presented in 25 kg packages in bulk for exporting to buyers.

Term of Export to Pakistan

There are challenges for the export of polymer materials for Iranian businessmen and one of the main reasons of which is the lack of business knowledge of economic activists in this field. The lack of knowledge and awareness among Iranian businessmen about polymer materials and how to export them causes the businessmen to incur losses due to high costs.

Although Iran is located in the neighborhood of Pakistan, polymer materials have a small sector for exports to Pakistan, and the country’s export potential is weak in this phase.

Due to the common borders with Iran, Pakistan is one of the best target countries for the export of polymer materials, including f7000 grade, which provides a satisfactory opportunity to businessmen and manufacturers to learn foreign trading knowledge and take great steps in this direction and overcome obstacles and export risks.

On the other hand, the export of F7000 to Pakistan can be considered one of the most prosperous exports for Iranian businessmen. This grade is a good option for trade and export to Pakistan due to its wide application and high economic efficiency.

Because Pakistan is one of the countries with low production facilities and weak technical knowledge for the production and business of these materials, and therefore this is a good opportunity for traders and producers to earn a lot of profit through trading with this country. The F7000 polyethylene is exported by various producing companies of this grade. However, the applicants of this grade are looking for high quality and reasonable price.

Irplastics company is one of the pioneers in the field of providing and supplying polymer materials and plastic raw materials and has been able to have many customers and buyers inside and outside the country. Because this company offers a high-quality product to its customers. Therefore, applicants can reduce their costs and earn more profit at an affordable price.

Export of f7000 grade is done in high volume due to its wide applications. Also, this polyethylene is used in various products, it has the ability to be recycled, and therefore it is more popular among customers.

Iran and Pakistan Borders

Choosing the best customs route for exporting polymer materials to Pakistan can help businessmen to save their costs. Pakistan is one of the neighbors of Iran, which has cultural and geographical similarities with our country. Currently, the land, air and sea borders are active so that traders can choose the best route for export according to their conditions.

One of the borders between Iran and Pakistan is 959 kilometers away, which is the common intersection of Iran, Pakistan and Afghanistan. The border ends in the southeast to the Oman Sea and is located near the city of Mirjaveh in Sistan and Baluchestan province. Also after crossing the Pakistani border regiment, five kilometers from this border is the city of Taftan in Pakistan.

In the past, the border routes between Iran and Pakistan included seven small markets, which currently have three active customs. Also, Mirjaveh-Taftan border (in Pakistan) is possible to commute by land, road and rail.

The routes of Jaleq (Iran)-Mashkil (Pakistan) as well as Pishin (Iran)-Mand (Pakistan) are road. However, one of the nearest crossings, which has a good potential for the export of polymer materials, is Rimdan Customs, which was recently established.

This customs is a border crossing whose terminal is in Dashtiari city of Sistan and Baluchistan province and it is 120 km away from Chabahar. This customs is 70 km away from Gwadar, 60 km from Jiwani, 200 km from Pasni and 700 km from Karachi. At the end of this crossing on the Pakistani side is Makran Coastal Highway and Karachi Port.

Rimdan border as a strategic and security border for exporting and importing goods to Pakistan is the most appropriate choice for businessmen. Also, due to Pakistan’s trading exchanges with countries such as China, Malaysia and etc., it is possible for businessmen to access these countries and develop more business and trading relations through this border. It is also possible to save on export costs by choosing the best way, and it is possible to earn more foreign currency for traders.

You could contact our company with Afshin Karmi trading team to purchase and provide the best polymer materials and plastic raw materials at a reasonable price, or to receive any advice on the export of HDPE F7000 to Pakistan. Our experts and consultants will respond you as soon as possible.